You have no items in your shopping cart.

Semiconductor

UL EHS Sustainability and SESHA have partnered together to develop courses specific to the semiconductor and high-tech industries, a collection of 18 modules designed by safety experts and adult learning specialists. The semiconductor and high-tech industries comprise a unique amount and level of job hazards, and finding quality, job-specific training on those hazards can be difficult. This new suite of online courses provides a comprehensive safety training foundation for SESHA partners.

Semiconductor Chemical Safety Part 2: Hazards, Controls and Emergency Actions

There are many chemicals you may be exposed to in semiconductor fabrication work. Each chemical has specific characteristics, hazards and safety measures associated with it. Take this course to learn what these chemicals are and how to protect yourself. Ideal learners are semiconductor employees.

$35.95

Semiconductor Chemical Safety Part 3: Extremely Hazardous Chemicals

There are many extremely hazardous chemical categories in semiconductor fabrication of which you need to be hyper-aware. Take this course to learn about nine of the categories, what they are and what to do in emergencies involving them. Ideal learners are semiconductor employees.

$35.95

Semiconductor Chemical Safety Part 4: Hazardous Gases and Control Systems (US)

Hazardous gases used in semiconductor fabrication facilities are typically stored outside of the manufacturing area and piped into the processing equipment. An accidental release of any gas could cause injury or death. In this course you will learn about the gases used, the hazards they pose and the controls used to protect workers. Ideal learners are semiconductor employees.

$35.95

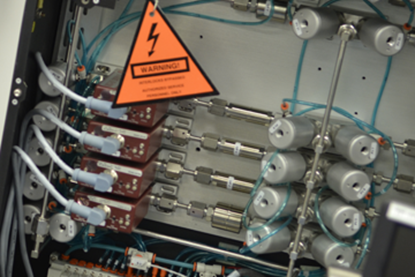

Semiconductor Hazardous Energy Control Part 1

Think safety first when working within semiconductor fabrication facilities. Become aware of the different types of hazardous energy that may injure or even kill you. Develop and practice a hazardous energy control program at your company using lockout/tagout procedures when servicing equipment or tools inside the fabrication facility. Ideal learners are semiconductor fabrication workers.

$35.95

Semiconductor Hazardous Energy Control Part 2

Think safety first when working within semiconductor fabrication units. Take this course to learn about the physical methods used to control hazardous energy found in your work area. Also learn about SEMI safety guidelines for interlock systems and hazardous energy isolation. Ideal learners are semiconductor fabrication workers, especially authorized employees.

$35.95

Semiconductor Hazardous Energy Control Part 3

Unexpected energization of semiconductor fabrication equipment being serviced or maintained can have fatal consequences. Take this course to learn how lockout/tagout procedures protect all employees and make the employees who perform maintenance and service work 100% responsible for their own safety. Ideal learners are semiconductor fabrication workers, especially authorized employees.

$35.95